INTRODUCTION:

An important resource to the life:

Starch is a carbohydrate founded in nature with very huge amount. It is found in bulbs, seeds, fruits of all variety of crops. Starch provides the crops with energy source in the process of dormancy and germination of crops. It is also the most important source of energy for animals and human beings. Starch plays a vital role in life. Statistics show that starch has currently had more than 4 thousand applications.

The natural starches are popularly used and have the commercial value mainly including tapioca starch, potato starch, corn starch and wheat starch. From the comparison of these starches, it’s known that ingredients and properties of tapioca starch are quite same with potato starch and much better than Corn starch and wheat starch. In addition, as for prices, potato starch is much higher than tapioca starch. With interesting advantages about properties and price, there is the evident growth demand for tapioca around the world. Concurrently, the common orientation for health creates the attention and the increasing desires for food not using genetic modification technology.

“GMO-Free” Food Ingredients

Corn Starch contains high GMO ingredient and potato starch also has a part of GMO ingredient when being treated. Therefore, Tapioca starch is chosen for food processing instead of potato starch or corn starch because tapioca starch does not contain GMO.

Applications of Tapioca starch in food starch and other industries

Vedan’s Tapioca starch is widely used for the following industries:

Filler:

Increasing the content of solids in all types of canned soups, ice-cream, fruit preservative agent and pharmaceuticals.

Binder:

Binding the products and preventing drying during cooking as all types of sausages and meat preservative, etc…

Stabilizer:

Using the high water holding capacity of the starch as in ice-creams, baking powders, etc…

Textile

Size for warp threads to reduce warp breaks and shredding on looms (Modified Starch preferred to this application)

Being used in printing and dyeing on fabrics: thicken dyes and act as colored substance.

Finishing Starch to improve stiffness and weight

Thickener:

Using the paste properties to apply for soup, baby food, all types of sauces, gravies, etc…

Paper:

Improving endurance, resistance to folding, waterproofing for paper, etc…

Improving its appearance and endurance

Being applied for all types of corrugated and laminated papers and cardboard boxes

Used as binder for industries:

Gypsum ceiling board

Feedstuff (Aqua-feed and Livestock Feeds)

Used in other industries:

Decomposable plastic bag

Tire industry

Plywood industry

Detergent

Packaging specification:

Using two-layer bags: outer layer covers PP, inter layer covers PE and is packaged according to two specifications: 50kg/bag and 20kg/bag

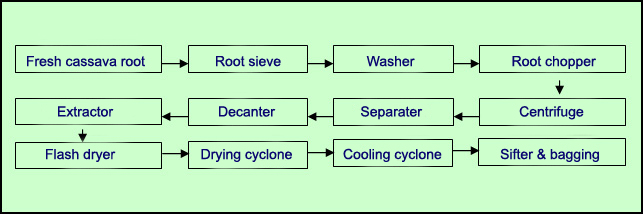

Advanced technology:

The diagram of processing tapioca starch of Vedan Vietnam as follows:

Tapioca (cassava) of Vietnam has high starch contents (over 30%) and high productivity because of being cultivated on fertile land.

Vedan directly purchases fresh cassava root from farmers which samples are experienced twice to identify their starch contents before being processed.

Equipment is imported from Japan, Europe and Thailand. With this modern equipment system and rich experience specialists, the production process is precisely and strictly controlled and checked to provide customers with the best quality starch.

At present, Vedan Vietnam has 2 operating tapioca starch plants including Phuoc Thai Plant in Dong Nai province, Phuoc Long Plant in Binh Phuoc Province with total capacity of over 100,000 tons per year.

Because the applications of Tapioca starch are inseparable from many other industries, Vedan also has plans to further expand the starch production at other provinces in Vietnam. It is predicable that such expansion will play an important role in promoting Vietnam agricultural development, as well as contributing to Vietnam economic growth. Let’s look forward to it.

♦ If you have more concerns or any questions relating to our company products, please click on Q&A Inbox to send an email or directly make a free call to hotline 1800599902, employees in charge will give you detailed feedbacks in the shortest time. Wishing you all the best.